pocket hole screw size guide

Pocket hole screw systems are essential for woodworking, offering versatility and strength in joining materials․ They are widely used in furniture, decking, and tight spaces, ensuring durability and precision․

1․1 What Are Pocket Hole Screws?

Pocket hole screws are specialized fasteners designed for woodworking, enabling strong, invisible joints․ They feature a coarse or fine thread for optimal grip in wood․ These screws are used with a pocket hole jig, which drills angled holes to guide the screw into the material․ Available in various lengths and finishes, they suit different wood thicknesses and project requirements․ Their self-tapping design eliminates the need for pre-drilling pilot holes, making them ideal for furniture, decking, and miter joints․ Durable and versatile, they ensure secure connections in a wide range of applications․

1․2 Importance of Proper Screw Size Selection

Proper screw size selection is crucial for ensuring strong, durable joints in woodworking projects․ Using screws that are too short may result in weak connections, while screws that are too long can split the wood․ Correct sizing ensures optimal grip and minimizes the risk of material damage․ Kreg provides a screw length chart and selector tool to help choose the right size based on material thickness․ This guidance is essential for achieving professional-grade results and avoiding common mistakes, ensuring your projects stand the test of time with structural integrity and reliability․

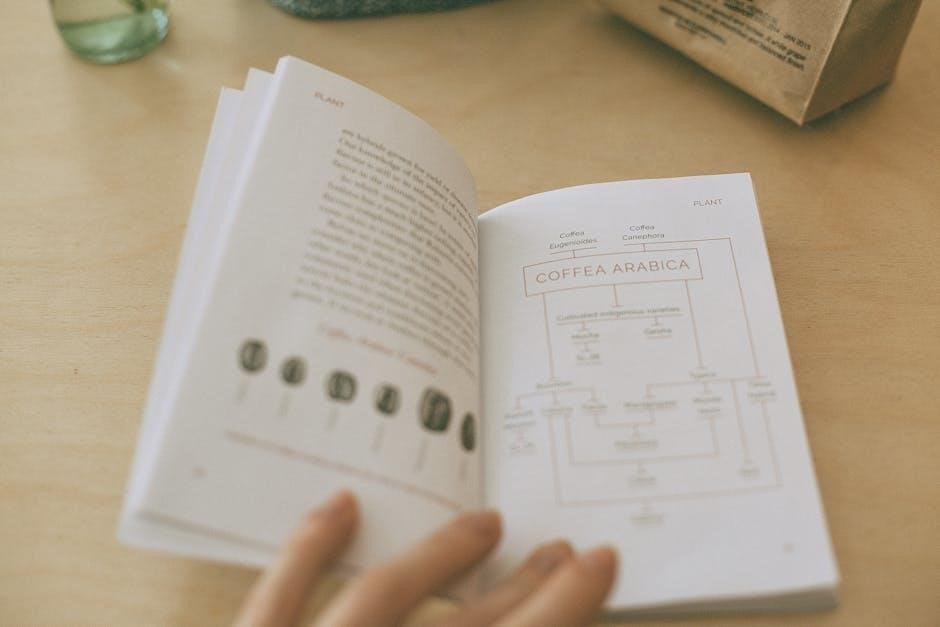

Understanding Pocket Hole Screw Sizes

Pocket hole screws come in various diameters and lengths, with charts guiding selection based on material thickness․ Proper sizing prevents splitting and ensures strong, durable joints․

2․1 Screw Diameter Options

Pocket hole screws are available in various diameters, typically ranging from 6mm to 10mm․ These options cater to different project requirements, ensuring optimal hold without excessive material damage․ The 6mm diameter is ideal for thinner materials like 1/2″ stock, while 8mm and 10mm diameters provide greater strength for thicker woods, such as 3/4″ or 1″ materials․ Selecting the right diameter is crucial for preventing splitting and achieving a secure joint․ Proper diameter choice also ensures compatibility with standard drill guides and jigs, making the assembly process smoother and more efficient․

2․2 Screw Length Selection Guide

Screw length is critical for proper joint strength․ For 3/4″ material, use 1-1/4″ screws; for 1․5″ stock, 2․5″ screws are ideal․ Always match screw length to material thickness to avoid over-drilling․ A selection chart is provided on Kreg jig packaging for easy reference․ Choosing the wrong length can compromise joint integrity․ Ensure screws penetrate at least halfway into the second piece for optimal hold․ Refer to the manufacturer’s guidelines for precise length recommendations tailored to your project needs․

Wood Thickness and Screw Size Relationship

Wood thickness directly influences screw size selection․ A screw length should match material thickness to ensure proper joint strength and avoid splitting․ Refer to the provided chart for precise sizing guidance․

3․1 Material Thickness Chart for Screw Length

A material thickness chart is crucial for selecting the correct screw length․ For 1/2″ stock, use 1″ screws; 3/4″ stock requires 1․25″ screws; and 1․5″ stock needs 2․5″ screws․ Thicker materials, like 2x4s, use 2․5″ screws, while 1″ stock uses 1․5″ screws․ Always match screw length to material thickness for optimal joint strength and to prevent splitting․ Kreg provides a detailed chart on their jig packaging for easy reference․ Ensure accurate measurements and proper tool setup for the best results in your woodworking projects․

3․2 Adjusting for Different Wood Thicknesses

Adjusting for different wood thicknesses ensures proper joint strength and prevents splitting․ Use the Kreg Screw Selector Tool for precise screw length recommendations․ For thinner materials, like 1/2″ stock, opt for shorter screws, while thicker materials, such as 1․5″ stock, require longer screws․ Always align the drill guide with the material’s edge and adjust the drilling depth accordingly․ Ensure the screw length matches the combined thickness of the materials being joined․ Refer to Kreg’s chart for specific guidelines, as incorrect sizing can compromise joint integrity and durability․

Materials and Thread Types

Pocket hole screws are available in various materials, including zinc-coated steel for indoor use and stainless steel for outdoor durability․ Fine and coarse threads suit different projects, ensuring optimal hold in wood, metal, or plastic, while materials like brass offer corrosion resistance for specific applications․

4․1 Screw Thread Types (Fine vs․ Coarse)

Fine-thread screws are ideal for harder woods and thin materials, providing a strong hold without splitting the wood․ Coarse-thread screws, with their deeper grooves, are better suited for softer woods and thicker materials, ensuring a secure grip․ The choice between fine and coarse threads depends on the wood type and thickness, as well as the desired holding power․ Proper selection ensures durability and prevents material damage․ Using the right thread type enhances joint strength and project longevity․

4․2 Material Compatibility (Wood, Metal, Plastic)

Pocket hole screws are compatible with various materials, including wood, metal, and plastic․ For wood, coarse-thread screws work best with softer woods, while fine-thread screws are ideal for harder woods․ When working with metal, self-tapping screws are recommended to ensure a secure hold․ For plastic, specialized screws with unique thread designs are available to prevent stripping․ Always select screws coated appropriately for the environment—zinc-coated for indoor use and stainless steel for outdoor applications․ This ensures durability and prevents corrosion․

Pocket Hole Jig Setup and Use

Pocket hole jigs simplify woodworking by providing precise drill guides and depth settings․ Use 6mm, 8mm, or 10mm sleeves for different screw sizes, ensuring proper alignment and adjustments․

5․1 Drill Guide Sizes (6mm, 8mm, 10mm)

Drill guides in 6mm, 8mm, and 10mm sizes accommodate various screw diameters, ensuring precise hole alignment․ For standard woodworking, 8mm is common, while 6mm suits thinner materials and 10mm for thicker stock․ Adjust the jig to match your screw size and material thickness for optimal results, preventing misalignment and enhancing joinery strength․ Proper guide selection is crucial for clean, professional-looking pocket holes in furniture, decking, or cabinetry projects․

5․2 Setting the Correct Drilling Depth

Setting the correct drilling depth is crucial for strong joints․ Use the jig’s adjustment screw to match the material thickness, ensuring the screw tip doesn’t protrude․ For 3/4″ stock, drill to 1/4″; for 1․5″ stock, drill to 1/2″․ Kreg jigs often include a depth guide chart․ Proper depth prevents screw tips from interfering with the joint’s strength and appearance, ensuring optimal hold without material damage․ Adjust carefully to avoid over-drilling, which can weaken the joint․ This step ensures your pocket holes are both functional and visually appealing in furniture or decking projects․

Common Applications of Pocket Hole Screws

Pocket hole screws are ideal for furniture, cabinetry, and decking․ They excel in outdoor projects and tight spaces, ensuring strong, hidden joints in wood, metal, and plastic materials․

6․1 Furniture and Cabinetry

Pocket hole screws are widely used in furniture and cabinetry for their strength and invisibility․ They are ideal for creating sturdy joints in table legs, shelves, and drawer assemblies․ The ability to drill precise pilot holes ensures minimal splitting, making them perfect for delicate woodwork․ Fine-thread screws are often recommended for hardwoods, while coarse threads work better for softwoods․ Using screws of appropriate length ensures secure connections without over-tightening, which can damage the material․ This method is especially popular for building custom cabinetry and restoring antique furniture, offering a professional finish every time․ The durability and ease of use make pocket hole screws a go-to choice for both professionals and hobbyists in woodworking projects․

6․2 Decking and Outdoor Projects

Pocket hole screws are ideal for decking and outdoor projects, offering durability and weather resistance․ They provide a secure connection for decking boards and outdoor furniture, ensuring stability over time․ Stainless steel or zinc-coated screws are recommended for outdoor use to resist rust and corrosion․ The screw length should match the wood thickness, with 2-1/2″ screws often used for 1-1/2″ decking boards․ Coarse threads are preferred for softwoods like pressure-treated lumber, enhancing hold without splitting․ This method allows for quick assembly and disassembly, perfect for seasonal adjustments or repairs, making it a reliable choice for outdoor woodworking․

6․3 Miter Joints and Tight Spaces

Pocket hole screws excel in miter joints and tight spaces, enabling strong, invisible connections․ Their compact design allows for precise alignment without visible hardware․ Fine-thread screws are often used in hardwoods for miter joints, reducing the risk of splitting․ The screw length should be slightly longer than the combined thickness of the materials being joined, typically ranging from 1″ to 1-1/2″ for most miters․ This technique ensures a flush finish and is ideal for intricate cabinetry and furniture, where traditional methods might fail․ It enhances both functionality and aesthetics in confined woodworking scenarios․

Screw Head Types and Finishes

Pocket hole screws feature square drive heads for easy installation․ Zinc-coated screws offer rust resistance for indoor projects, while stainless steel screws provide durability for outdoor applications․

7․1 Square Drive vs․ Other Drive Types

Square drive screws are favored for their torque resistance and ease of use․ Unlike Phillips or flathead drives, square drives minimize cam-out, reducing stripped screws․ This ensures secure, wobble-free connections, especially in tight spaces like miter joints․ The square shape provides a larger contact area, improving control during driving․ For outdoor projects, pairing square drives with zinc-coated or stainless steel screws enhances durability․ This combination is ideal for decking and heavy-duty applications, offering both strength and reliability across various woodworking tasks․

7․2 Zinc-Coated vs․ Stainless Steel Screws

Zinc-coated screws offer excellent rust resistance, making them ideal for indoor projects, while stainless steel screws provide superior durability for outdoor use․ Zinc-coated options are cost-effective and suitable for most woodworking tasks, but stainless steel is better for harsh environments․ Both options are available in various lengths and thread types, ensuring versatility․ For decking or high-moisture areas, stainless steel is recommended․ Zinc-coated screws are perfect for standard applications, balancing performance and affordability․ Choose based on project requirements and environmental conditions for optimal results․

Selecting the Right Screw for Your Project

Selecting the right screw involves considering material thickness, screw length, and project requirements․ Use charts or tools like the Kreg Screw Selector for precise recommendations․

8․1 Screw Length Recommendations

Screw length should match the thickness of the materials being joined․ For example, 3/4″ screws are ideal for 1/2″ stock, while 1-1/4″ screws suit 3/4″ materials․ Always ensure the screw is long enough to securely hold the joint without over-extending․ Kreg provides a detailed chart to help select the correct length based on specific project needs․ For thicker materials, longer screws are recommended to maintain strength and durability․ Using the right length ensures proper alignment and prevents damage to the workpiece, especially in outdoor or heavy-duty applications․ Refer to the Kreg screw length chart for precise guidance․

8․2 Using the Kreg Screw Selector Tool

The Kreg Screw Selector Tool simplifies choosing the right screws for your project․ By inputting material thickness, screw type, and application, it provides precise recommendations․ This tool ensures optimal screw length and thread type selection, enhancing joint strength and durability․ It also considers factors like wood species and project type, offering tailored solutions․ The tool is available online, making it easy to access and use․ By leveraging this resource, you can avoid guesswork and ensure your projects are securely and professionally assembled every time, saving time and effort in the process․

8․3 Quantity and Packaging Options

Kreg pocket hole screws are available in various packaging options to suit different project needs․ From small packs for minor repairs to bulk options for large-scale projects, Kreg offers flexibility․ Screws are sold in packs of 50, 100, 250, or 500, depending on the size and type․ This ensures you have enough screws without excess․ Additionally, Kreg provides screws in different finishes like zinc-coated or stainless steel, catering to various applications․ The Kreg Screw Selector Tool also helps determine the right quantity for your project, ensuring you buy exactly what you need, optimizing cost and efficiency․

Kreg Pocket Hole Screws and Accessories

Kreg offers a range of screws and accessories, including drill guides and charts, to ensure precise pocket hole drilling and screw selection for woodworking projects․

9․1 Kreg Screw Length Chart

The Kreg Screw Length Chart is a handy reference guide that correlates screw lengths with material thickness for optimal joint strength․ It specifies that 1-1/4″ screws are ideal for 3/4″ stock, while 1-1/2″ screws suit 7/8″ material․ For thicker woods, like 1-1/2″ stock, 2″ screws are recommended․ The chart also covers finer details, such as using 1″ screws for 1/2″ materials and 2-1/2″ screws for heavier applications․ Available on Kreg jig packaging, the chart ensures precise selection, preventing over-tightening and material splitting, making it an essential tool for woodworking projects of all sizes and types․

9․2 Kreg Jig Compatibility Guide

The Kreg Jig Compatibility Guide ensures seamless integration of Kreg screws with various materials and jig setups; It provides detailed charts to match screw lengths and diameters with specific jig models, such as the Deluxe Pocket Hole Jig Kit․ The guide highlights compatibility with 6mm, 8mm, and 10mm drill sleeves, ensuring precise drilling for different projects․ It also covers material thickness ranges, from 1/2″ to 2×4″ stock, and recommends screw lengths for each scenario․ This guide is printed on Kreg jig packaging, offering a quick reference for woodworking enthusiasts to achieve professional-grade results․ It emphasizes proper alignment and drill depth for secure joints․

Tips for Avoiding Common Mistakes

Avoiding common mistakes with pocket hole screws requires attention to drilling depth, proper screw selection, and avoiding over-tightening․ Ensure precise alignment and use the correct jig setup for secure joints․

10․1 Drilling Depth and Angle

Drilling depth and angle are critical for proper pocket hole functionality․ Use a depth guide to ensure screws sit flush without over-drilling․ Maintain a consistent 15-degree angle for optimal joint strength․ Incorrect angles can lead to weak connections or wood splitting․ Always refer to the Kreg chart for precise depth settings based on material thickness․ For thinner materials, consider using a micro jig to avoid over-drilling․ Proper alignment prevents screws from protruding, ensuring a clean finish․ Misaligned holes can result in uneven surfaces or joint failure․ Double-check your drill guide setup before starting to ensure accuracy and avoid costly mistakes․

10․2 Over-Tightening and Stripping Screws

Over-tightening and stripping screws are common mistakes that can weaken joints and damage wood․ Use a torque-controlled drill to avoid excessive force․ If a screw starts to strip, stop immediately and assess the issue․ Stripping often occurs due to drill guide misalignment or using the wrong screw length․ Always refer to the Kreg screw chart for proper sizing․ Apply even pressure and avoid overtightening, as this can compromise the screw’s grip․ For delicate materials, consider pre-drilling pilot holes to reduce friction and prevent stripping․ Regularly inspect screws for signs of wear to ensure long-lasting durability in your projects․

Selecting the right pocket hole screws ensures strong joints and professional-grade results․ Always consider material thickness, screw length, and proper jig setup for optimal durability and performance․

11․1 Summary of Key Points

Pocket hole screw systems offer a reliable method for joining materials, ensuring strength and durability․ Proper screw size selection is critical, considering material thickness, screw length, and thread type․ Using resources like the Kreg Screw Selector Tool and material thickness charts guarantees accurate choices․ Understanding screw diameter options, drill guide sizes, and adjusting for different wood thicknesses enhances project outcomes․ Common applications include furniture, decking, and miter joints․ Always follow drilling depth guides and avoid over-tightening to prevent errors․ By mastering these principles, you can achieve precise, long-lasting joints in various woodworking projects․

11․2 Final Thoughts on Pocket Hole Screw Selection

Selecting the right pocket hole screws ensures strong and durable joints in woodworking projects․ Proper screw length, diameter, and thread type are crucial, depending on material thickness and application․ Using tools like the Kreg Screw Selector and material thickness charts simplifies the process․ Avoid common mistakes by setting the correct drilling depth and avoiding over-tightening․ Whether for furniture, decking, or miter joints, choosing the appropriate screws guarantees professional results․ By following these guidelines, woodworkers can achieve precise, long-lasting connections, elevating the quality of their projects․